Sugar Mill Bagasse Cogeneration Project

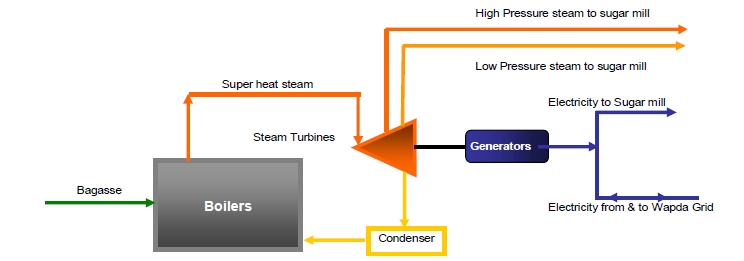

Bagasse from sugar cane used in boilers to generate steam and electricity for sugar mills is a renewable energy fuel. The use of bagasse reduces greenhouse gas (GHG – carbon dioxide) emitted by fossil fuel (diesel, furnace oil, natural gas and coal) consumption as the need for fossil fuel based grid electricity is reduced or eliminated. Generating your own energy with bagasse ensures a reliable source of steam and electricity for the sugar mill and in fact you can sell the surplus electricity.

Your sugar mill may be planning to install a high pressure bagasse fired cogeneration system in the near future or may be in the process of installing one. Recovering the equipment capital cost simply by relying

on savings from switching to a high pressure boiler using bagasse may not provide the best return on investment. Your investment payback will be much better and faster by developing the project under UNFCCC (United Nations Framework Convention on Climate Change) Clean Development Mechanism (CDM). This platform allows you to sell the Certified Emission Reduction (CER) credits generated from your bagasse cogeneration facility, providing additional revenue to enhance your return on investment.

Example: A 20 MW cogeneration unit

Example: A 20 MW cogeneration unit comprised of 110 tons per hour high pressure boilers and double extraction condensing type turbine-generator can offset about 25,000 tons per year of greenhouse gas (CO2) to generate equivalent Certified Emission Reduction (CER) credits. This will provide an additional revenue stream of $ 250,000 each year for the CDM project cycle of 10 years (calculations are based on assumption that 3,500 tons per day capacity sugar mill is operated at least 180 days per year).

Contact us to provide

- The technical details and specifications of your bagasse cogeneration system

- Sugar mill operational data such as seasonal running capacity and amount of bagasse produced in a year

- The investment made or needed and the annual operating expense of the bagasse cogeneration system that you plan to install, are installing, or you have recently installed

The CDM Process

- Polar Design Studio will complete the Clean Development Mechanism (CDM) Project Design Document (PDD) applying the prescribed methodology (PDD development 1 – 3 months)

- On finalizing the PDD, a CER purchase agreement (ERPA-Emission Reduction Purchase Agreement) will be negotiated with a potential buyer from the developed countries

- You will obtain a letter of approval (LoA) from the DNA (Designated National Authority – CDM Pakistan) and Environmental Impact Assessment (EIA) approval from the Ministry of Environment

- A UNFCCC approved DOE (Designated Operational Entity) firm will be hired to perform the services of PDD validation and registration with the UNFCCC CDM Board – (time taken 3 – 6 months)

- On successful registration of the project with the UNFCCC CDM Board, project monitoring outlined in the PDD document will be initiated and yearly project monitoring data recorded will be collected for CER verification by DOE. The DOE will register the CERs with the UNFCCC CDM Board each year for the project life cycle

- The CERs released by UNFCCC CDM Board each year will be transferred to the buyer who will pay the CER price negotiated in the ERPA agreement

- In a CDM project the process of project monitoring and verification is conducted each year for the project lifecycle of 10 or 21 years

- Our Role

- Polar Design Studio in partnership with the project owner will complete: CDM-Project Design Document development, validation, registration, monitoring and CER transfer during the project life cycle

- Polar Design Studio will ensure CER monitoring is carried out each year and the CERs generated are verified, registered and transferred to the buyer and funds released by the buyer

Next Important Steps

- Provide us with the preliminary information of your bagasse co-generation project.

- We will give you our expert advise on Certified Emission Reduction (CER) revenue potential

- On your approval of our service terms, sign an agreement with us for CDM project development