Anaerobic Bio-digester Plant Types

Compressed Natural Gas (CNG) Bio-digester Plant main Sections

- Bio-waste receiving and processing

- Bio-digester plant and Bio-digester Effluent Processing & Handling

- CNG processing & filling station

Combined Heat & Power (CHP) Bio-digester plant main Sections

- Bio-waste receiving and processing

- Bio-digester plant and Bio-digester Effluent Processing & Handling

- Power and heat (steam/hot water) generation

Tri-generation (electricity, heat & cooling) Bio-digester plant Sections

- Bio-waste receiving and processing

- Bio-digester plant and Bio-digester Effluent Processing & Handling

- Power and heat, steam/hot water/chiller cooling for cold storage

- Electricity for Tube Wells

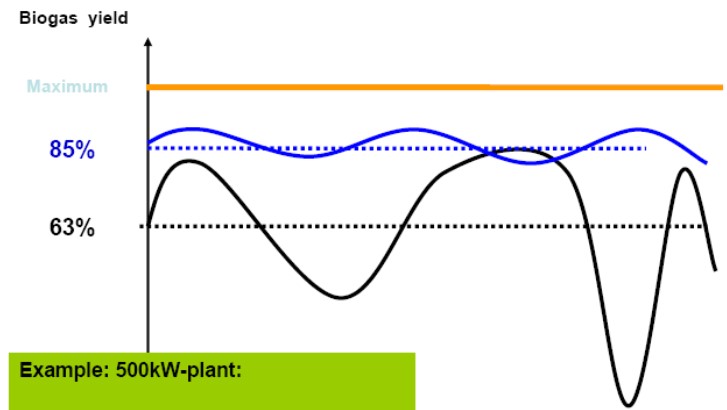

Bio-digester Plant Production (Example)

- Organic feed stock mix (manure, poultry, fat, molasses, vegetable wastes)

- Mix bio-waste per day: 50 tons

- (manure 10 tons, vegetable waste 17 tons, oil/fats/molasses 6 tons, food/bakery waste 3 tons)

- Biogas Plant production:

- CNG generation: 4,135 kg/day (fuel for more than 1,000 vehicles)

- Or CHP Plant electricity generation: 9,568 kWh/day (power for 1,500 houses)

- CHP Plant steam generation: 0.76 ton steam/hour (at 150 psig, 366 F)

- In tri-generation steam generated is used for adsorption chiller cooling

- Solid & Liquid Fertilizer Production

- Organic fiber generation: 7,000 kg/day ( potting soil, board making)

- Liquid fertilizer generation: 77 tons/day (agricultural, reduces urea need)

- CDM CERs

- CDM CER generation: 55 CER/day (18,700 CER/year)

Plant Investment

Total capital investment approximately = $ 1.56 million (Rs 133,099,200)

Plant Revenue Streams

Revenue from CNG, CHP or Tri-generation

Revenue from organic fertilizer

Revenue from CER

Plant Operating Expense

Maintenance & Operation

Waste transportation & Handling

Administration & Accounts

Plant Earnings

Positive Return on Investment