Agriculture based economies present an opportunity for a sustainable business model that is profitable apart from providing a permanent solution for proper disposal of large quantities of manure generated at dairy farms and other large live stock operations. Major problems associated with waste generated from livestock operations are surface and ground water contamination, increase in phosphate levels, pathogens and air pollution caused by odor, dust, ammonia and methane. Climate change has led to a serious concern about large quantities of methane emissions from existing manure management and storage practices contributing to global warming. Methane is 21 times more potent than carbon dioxide

as a greenhouse gas.

Silica Solar LLC has proposed a business model to generate renewable electricity by anaerobic digesters at dairy farms, food and vegetable process plants, bakery product plants, and sugar waste and municipal waste water plants. This will not only provide a long term manure and waste effuent management system to the companies but will prevent local pollution and reduce global warming emissions. Biogas is a mixture of Methane and CO2 and is produced from the decomposition of organic matter. Converting the manure and effluent waste disposal problem into a profitable business enterprise by generating the following commodities for sale:

- Renewable electricity

- Hot water and steam

- Fertilizer/bio-solids

- Carbon dioxide offsets and Renewable energy credits

Besides generating revenue, the opportunity reduces expenditure spent on manure and effluent waste management and disposal at the plant that can be counted as additional savings for the companies from the project.

Farmers rely heavily on government subsidies to manage commodity prices and to show profitability. Over the years there has been a steady decline in the dairy industry driven by high feed cost and skyrocketing energy prices leading to tight profit margins for the farmers. Turning a waste liability into a profitable business can generate revenues that reduce the impact of declining commodity prices and diversify farm income. The anaerobic digester waste to energy plants will allow the farmers to expand and grow their livestock operations by adding an additional source of revenue through farm waste management while reducing the impact of global warming.

Anaerobic Bio-digester Plant Types

Compressed Natural Gas (CNG) Bio-digester Plant main Sections

- Bio-waste receiving and processing

- Bio-digester plant and Bio-digester Effluent Processing & Handling

- CNG processing & filling station

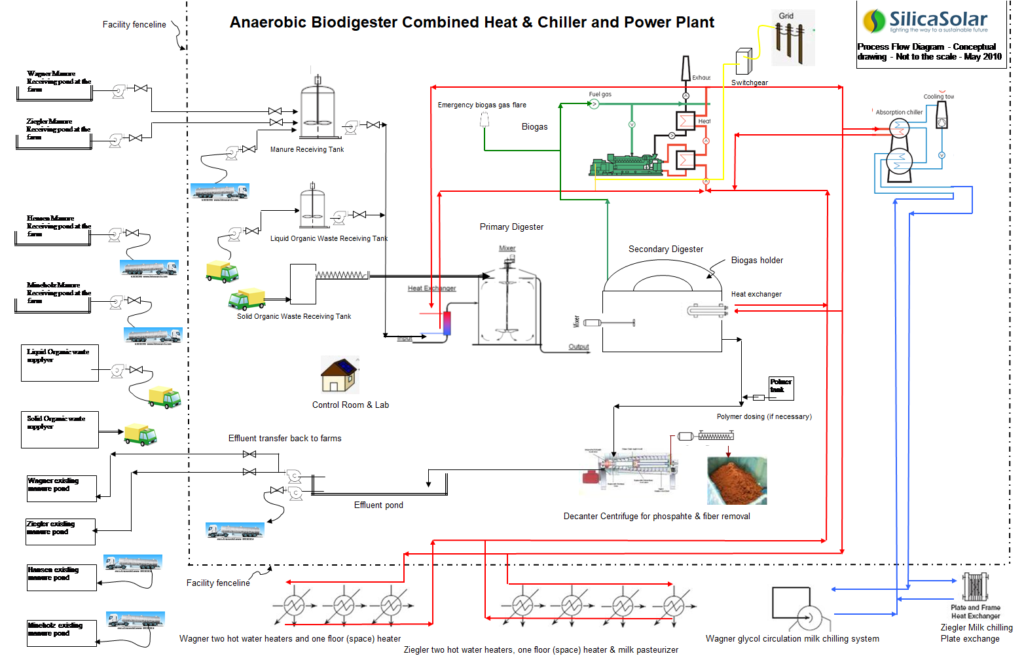

Combined Heat & Power (CHP) Bio-digester plant main Sections

- Bio-waste receiving and processing

- Bio-digester plant and Bio-digester Effluent Processing & Handling

- Power and heat (steam/hot water) generation

Tri-generation (electricity, heat & cooling) Bio-digester plant Sections

- Bio-waste receiving and processing

- Bio-digester plant and Bio-digester Effluent Processing & Handling

- Power and heat, steam/hot water/chiller cooling for cold storage

- Electricity for Tube Wells

To learn more download presentation

Our Biodigester Technology Provider

Silica Solar AD biodigester technology providers for projects are Krieg & Fischer Ingenieure GmbH, from Germany. The company has approximately 120 reference plants to its credit: agricultural and industrial, one and two stage mesophilic and thermophilic wet and dry fermentation plants; biogas plants for fermentation of cattle, pig, poultry manure, co-fermentation and bio-waste fermentation plants. The fermentation of wide range of substrates from grass silage, corn silage, bio-waste, manure, fats, kitchen wastes and many other organic wastes are part of spectrum. Their designed plants are operating in Germany, Japan, Italy, Lithuania, Slovakia, Switzerland, Spain, France, Canada and the USA. They provide us complete technology services from, planning, detailed engineering, construction supervision, commissioning, training, guarantee testing and after service technical support to optimize plant operation, maintenance for maximizing return on investment.